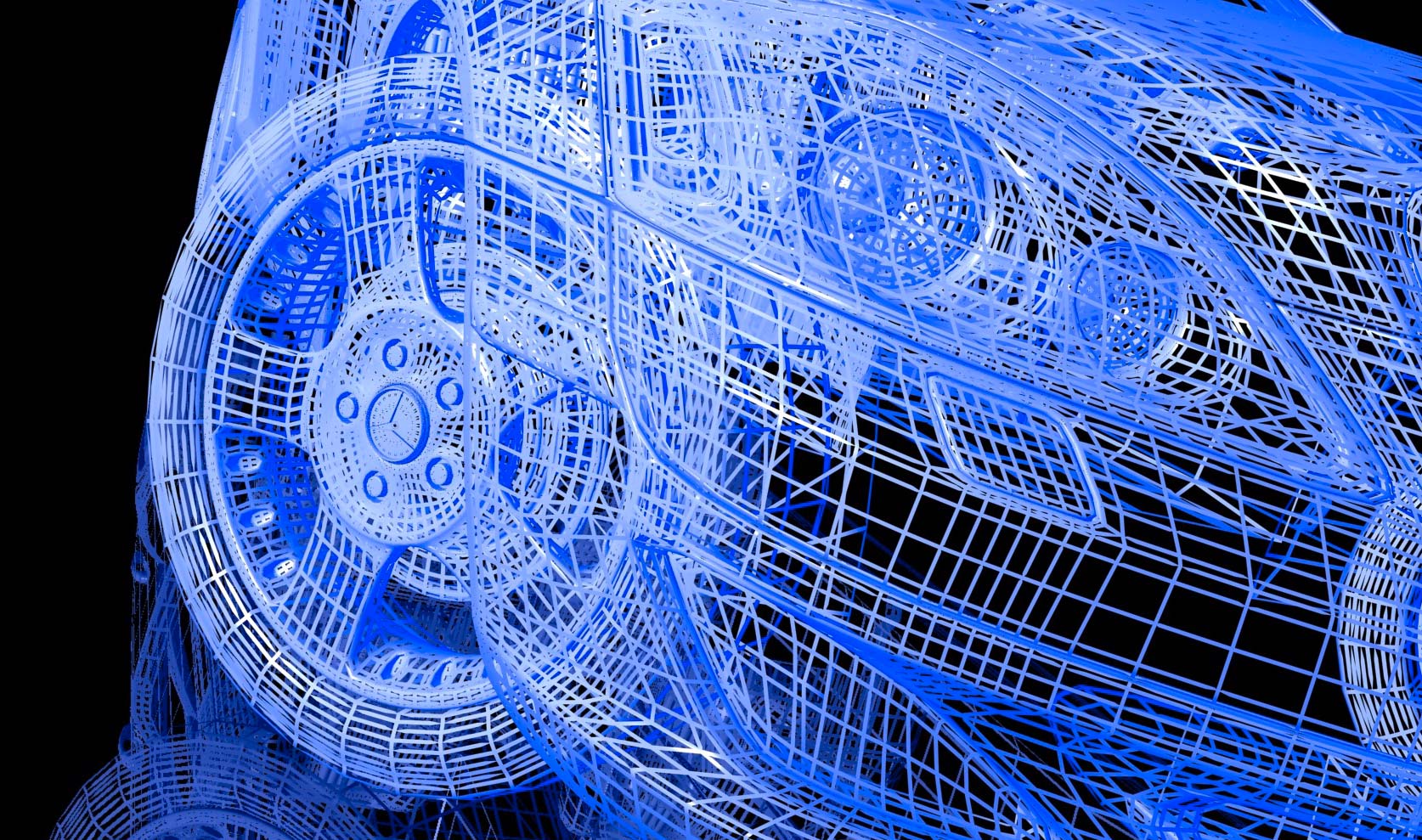

Schneider Form – More than 60 years of experience

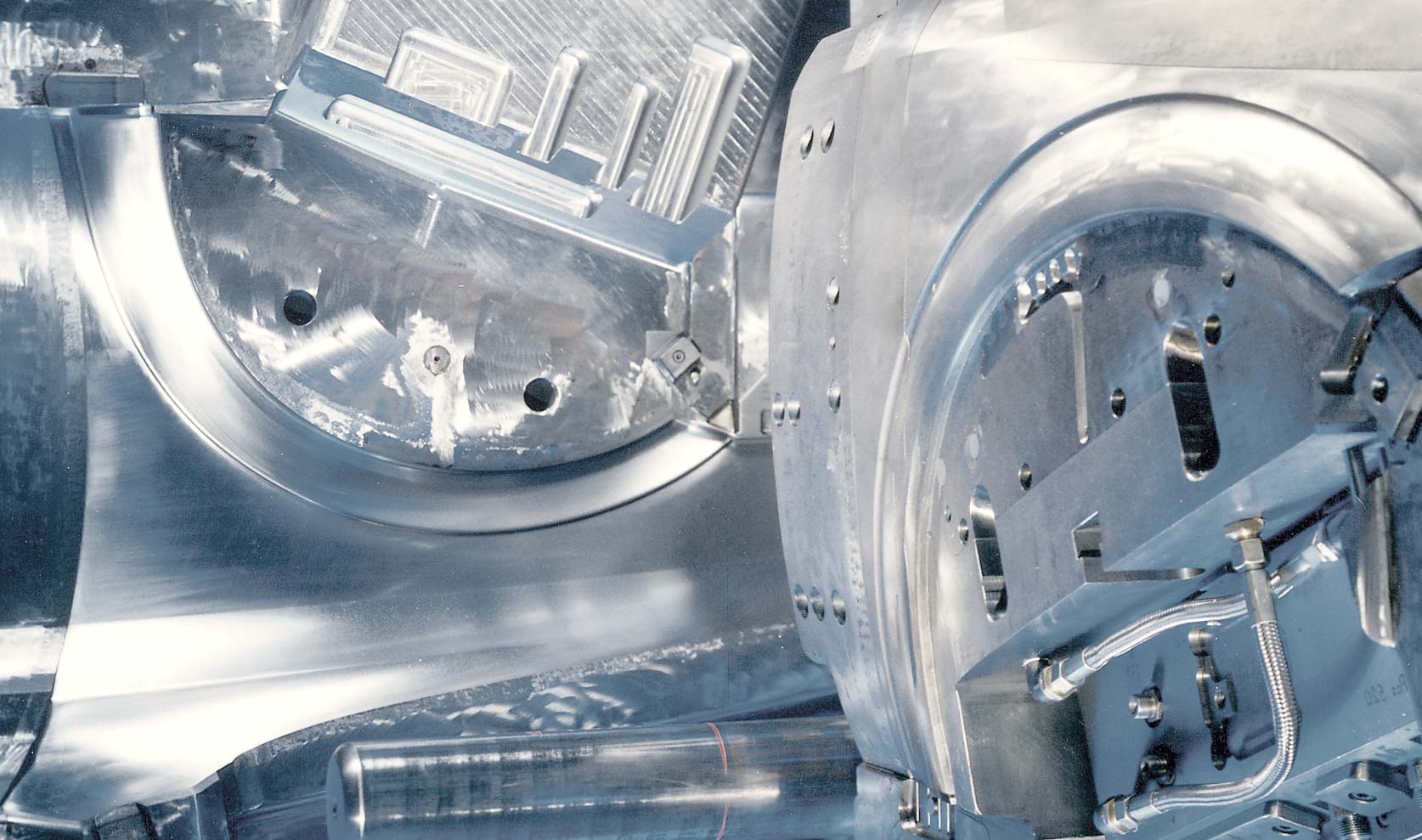

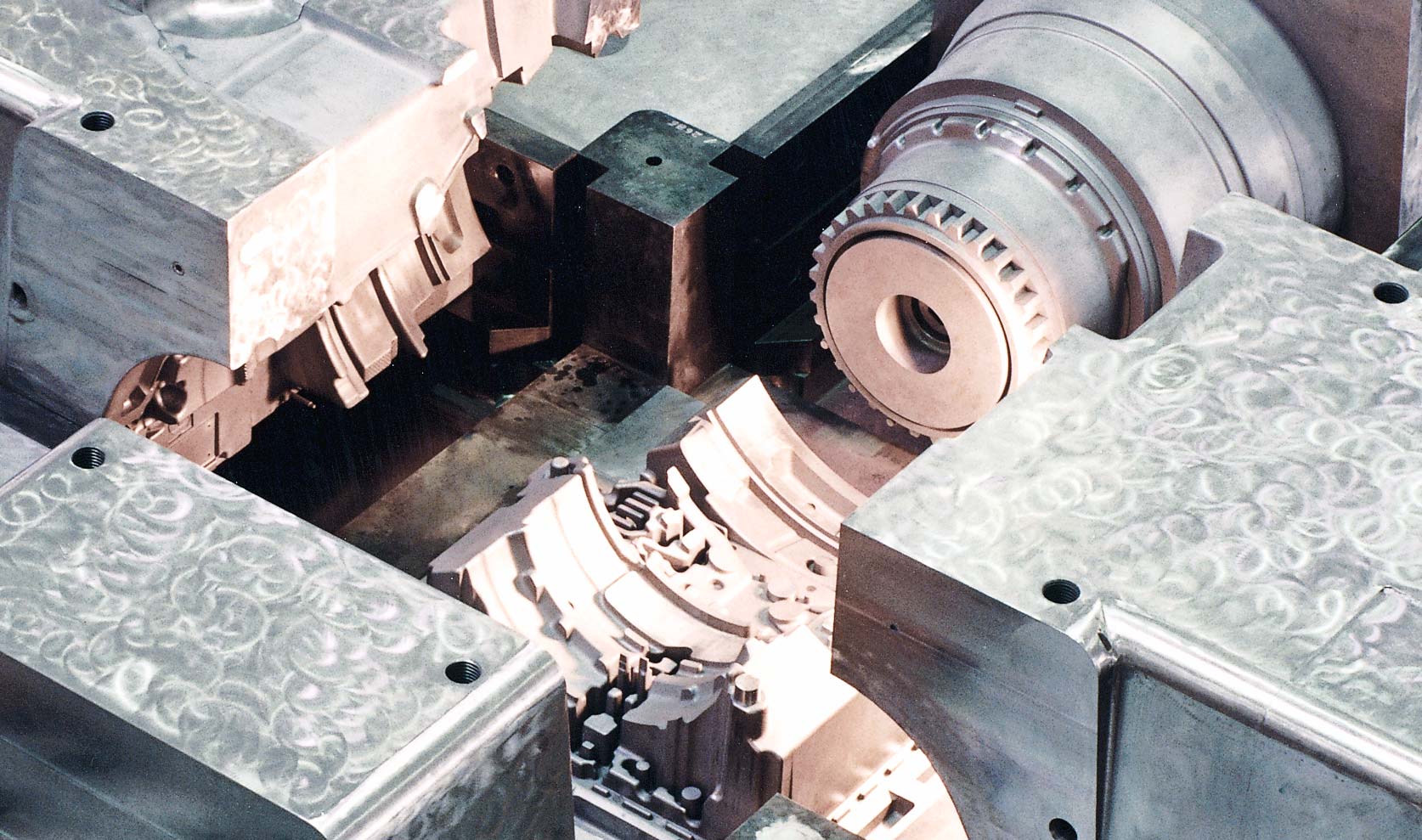

With more than 300 employees in mould making and component design, we are now the specialist for high-quality injection and die-casting moulds. We are the only company in the industry that is able to design your components and manufacture the necessary tools. You don’t have to bother with coordinating the design house and the toolmaker. You instead will get a producible product without any redundant change loops.