Seminar “tool technology for large plastic components”

This workshop is for designers, developers, quality engineers and tool purchasers who, at an early stage play an important role and thus have an influence upon producibility, development periods and costs. To be sure, our pragmatic approach does not replace carefully acquired know-how. But it improves your basic understanding of a tool’s functions and the injection-moulding process and of critical design and development stages.

Contents

- Tool making – general definition

- Temperature control – problems and possibilities

- Gating systems – hot runner, film gate, tunnel gate

- Tool centering – impact upon split lines

- Ejectors and sliders – types and operating mode

- Tool costs – use of materials and cost drivers

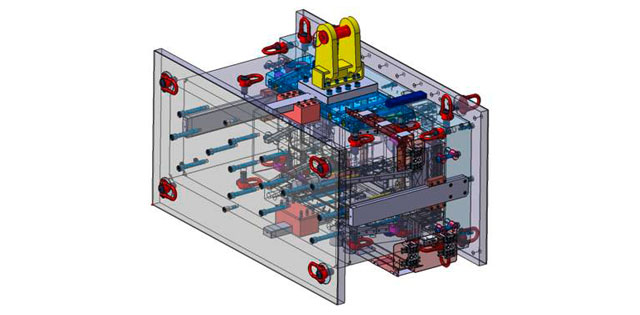

- Practical use of a tool – a bumper tool’s functions

Demoulding

- Demoulding types – impact upon design and engineering

- Critical areas of bumper demoulding (foglamp / wheel house flange/soft nose)

- Examples of complex demouldings (complex slider systems)

- Life next to the machine – cinematics and part removal

Injection process

- Gating position, mould flow

- Injection pressure, filling pressure, flow lines and weld lines

- Component removal, cycle times

Various topics and examples will be explained during the tour of our plant.

Duration:

1 day (9 am – 4 pm)

Place:

Schneider Form GmbH, D-73265 Dettingen/Teck, Germany

Appointments and registration:

As a rule, we provide trainings for groups (10 people at max.) Places are reserved for other, individual participants.

Please just ask us for dates and prices.

Mr. Christian Sehl

Email: c.sehl@Schneider-Form.de

To ensure that we meet our visitors’ expectations, we value your opinion. At the end of each seminar, we therefore hand out a sheet for you to give us your ideas and feedback.

Since 2009, we have trained more than 600 people in such seminars, and their average rating was “very good”.