Range of services

Our range of products and services is geared to the die-casting dies’ development process. We can support you with filling and setting simulations in the gating and spillway dimensioning as early as at the development and design stage. Our refined customer and product templates make sure that the design of the tools leaves nothing unconsidered and allow us to be creative where it is most promising.

Project managers and planners make sure that you can be informed about the tool’s status at any given point in time and that the schedule is kept. We prepare initial sampling reports in accordance with VDA or your specifications. If you want, we will also take over your project’s modification management. This is particularly important for larger volumes of tools in particular, as you always have to know which design changes have been realised on a variant.

Since die-casting dies are subject to a certain wear and tear, we are also prepared to do all the maintenance work for you. Carefully planned and swiftly carried out maintenance cycles greatly improve your tools´ availability. A thought-through spare part management and inspection records for, e.g., leakage and flow tests make sure that your tool is ready when you need it.

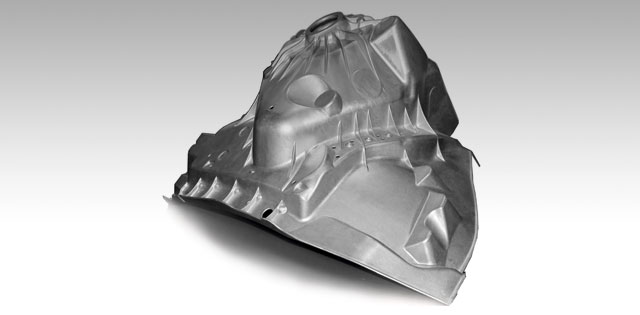

Whether we develop changeover concepts with you that allow an exchange of contour inserts in the machine, design locking concepts for 3-plate dies or build a vacuum die that has to have a structure free of pores – we will always come up with a solution that is not only innovative but also production-safe.